Re: POET's supply chain questions

in response to

by

posted on

Aug 23, 2024 06:58PM

Thanks B&C for the breakdown. I was trying to answer my own question by re-reading the POET website. I found the information below helpful. So it sounds like Silterra has the main job of making interposers on a wafer, with their Billion$ fab, then it goes to SPX where they dice and customize the chips in their Millions$ facility. This is what needs to be replicated for the China +1 strategy.

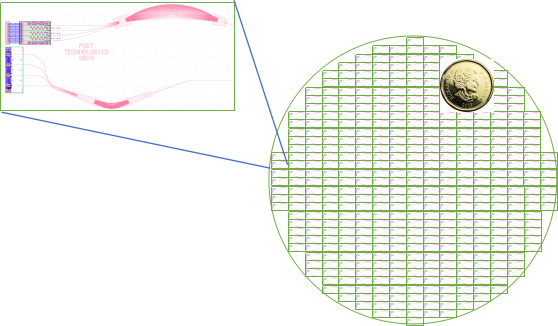

Hopefully, Silterra can keep up, or it'll be easy enough to add a fab partner to meet demand. Yah, yah, I am getting ahead of the game here. Let's sell a bucket full before a tanker full. Here is the helpful text from POET; 500 interposers from an 8" wafer:

How does the POET Optical Interposer achieve chip-scale integration and wafer-scale assembly and testing?

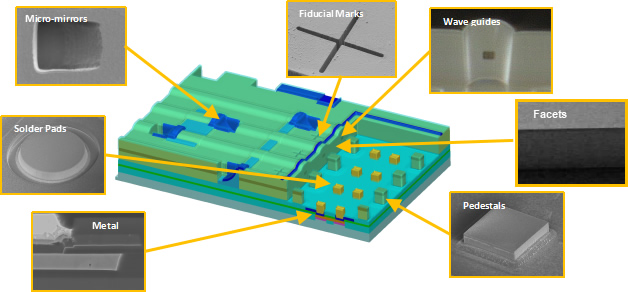

Combined, all the features noted above and those shown below, enable the passive “pick-and-place” assembly of the POET Optical Interposer, eliminating the need for active optical alignment required by conventional approaches.

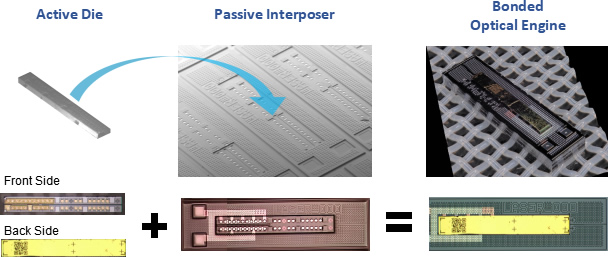

To retain its elegant design and to enable placement of devices without the costly procedure of active alignment with each device placement, lasers and other active devices are designed to be “flip-chipped” onto the surface of the POET Optical Interposer. All passive components (mux – de-mux filters, gratings, spot-size converters, etc.) are built into the POET Optical Interposer waveguide layer. Any active device, including lasers, modulators, detectors, etc., can be coupled into the waveguide. Because loss from the waveguides is low across a wide energy spectrum, including visible and non-visible light, the POET Optical Interposer can be used to enable a wide variety of applications, providing a truly versatile platform technology.

An Optical Interposer-based Optical Engine for a 100G transceiver

From fabrication of an 8” POET Optical Interposer wafer, to the placement of active devices and fiber blocks onto the wafer using pick and place tools, to the testing of each Optical Engine, to the capping, sealing and singulation of the devices, the entire process is done at wafer scale, providing an across the board reduction in cost.

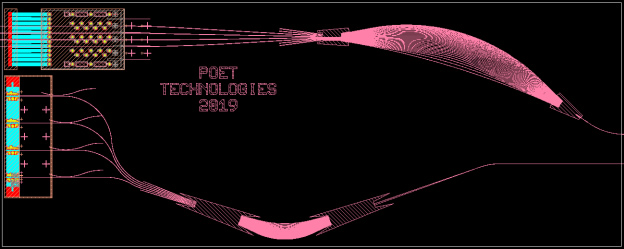

The power of wafer-scale fabrication, test and assembly – drives down cost with unlimited scalability.

A POET Optical Engine for a 400G transceiver – over 500 devices processed at the same time on a standard 8”silicon wafer.