Horizontal drilling

posted on

Nov 17, 2011 06:36PM

Developing large acreage positions of unconventional and conventional oil and gas resources

First of all, I agree with Robert Macaulay’s comment that Falcon’s testing of the Shenondoah-1 well was a resounding success.

“Falcon CEO Robert Macaulay commented, "I am very pleased with the results of the Shenandoah-1 well test. The Velkerri results support our belief in recoverable hydrocarbons in the deepest part of the Beetaloo Basin. They also prove that these particular shales can be fracture stimulated which is a crucial first step in the exploration and appraisal process. The Moroak sandstones continue to be a target of interest and the information gained from testing will help with prospecting for these targets elsewhere in the Basin. The Lower Kyalla result is likewise encouraging, we will be working through the data to understand it better before committing our plans to paper on the next steps. Finally, a very extensive sequence of operations was carried out safely and successfully - I am very happy with the performance of our staff and contractors in this regard." “

Secondly, to effectively exploit the resources in the Beetaloo basin can be done only through horizontal drilling. The reason being that the Middle Velkerri is about 600 feet in thickness, so a vertical bore isn’t going to expose as much surface in the reservoir as the horizontal bore would.

Explanation By Lynn Helms

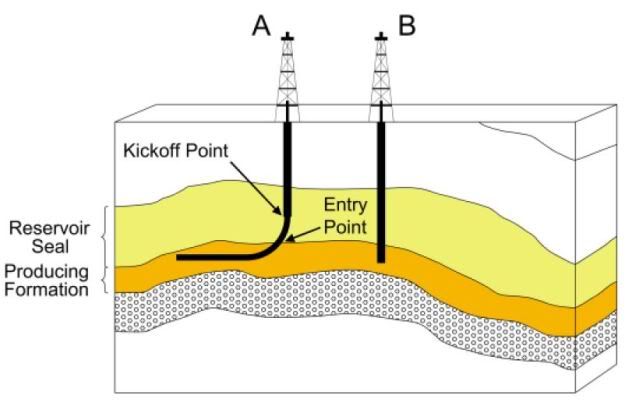

Horizontal drilling is the process of drilling a well from the surface to a subsurface location just above the target oil or gas reservoir called the “kickoff point”, then deviating the well bore from the vertical plane around a curve to intersect the reservoir at the “entry point” with a near-horizontal inclination, and remaining within the reservoir until the desired bottom hole location is reached.

Purpose

Most oil and gas reservoirs are much more extensive in their horizontal dimensions than in their vertical (thickness) dimension. By drilling a well which intersects such a reservoir parallel to its plane of more extensive dimension, horizontal drilling exposes significantly more reservoir rock to the well bore than would be the case with a conventional vertical well penetrating the reservoir perpendicular to its plane of more extensive dimension.

Greater length of producing formation exposed to the wellbore in a horizontal well (A) than in a vertical well (B). Source: Energy Information Administration, Office of Oil and Gas.