The Graphene-Info newsletter (July 4, 2023 )

posted on

Jul 04, 2023 10:11AM

Hydrothermal Graphite Deposit Ammenable for Commercial Graphene Applications

Cannot read this? View it online here

Researchers at ETH Zürich, Empa, ICFO and Japan's National Institute for Materials Science have created an antenna for light sources on a chip using an unusual placement of a semiconductor material. In the future, efficient nanoscale LEDs and lasers could be produced in this way.

Modern data transmission is based, among other things, on the fact that information can be sent quickly through optical fibers in the form of light beams.

The light sources are technologically challenging. The researchers at in the recent study have laid the foundations for tiny, efficient light sources. For their mini light sources, the researchers use rules of quantum mechanics and a surprising antenna solution.

Scientists from Nanyang Technological University (NTU), Panasonic Factory Solutions Asia Pacific Pte. Ltd. (Panasonic) and Singapore Centre for 3D Printing (SC3DP) have developed a multi-material printer using multi-wavelength high-power lasers, for quick and easy 3D printing of smart, flexible devices.

The multi-material printer works by utilizing varying wavelengths of laser, creating thermal and chemical reactions capable of transforming common carbon-based materials (polyimide and graphene oxide) into a new type of highly porous graphene. The resulting structure printed with this new graphene is not only light and conductive, but it can also be printed or coated onto flexible substrates like plastics, glass, gold and fabrics, creating flexible devices.

Singapore-based ship management company, Eastern Pacific Shipping (EPS), has announced that it has teamed up with Canada-based coatings company Graphite Innovation & Technologies (GIT) to implement its graphene-based, biocide-free propeller coating across its fleet.

EPS plans to boost the performance of its vessels by applying GIT’s eco-friendly, highly durable, and ultra-low friction foul release coating, aiming to improve and maintain CII rating over the drydocking cycle.

Researchers at Queen Mary University, University of Sussex and University of Brighton have integrated graphene into seaweed to create nanocomposite microcapsules for highly tunable and sustainable epidermal electronics. When assembled into networks, the tiny capsules can record muscular, breathing, pulse, and blood pressure measurements in real-time with ultrahigh precision.

The team explained that much of the current research on nanocomposite-based sensors is related to non-sustainable materials. This means that these devices contribute to plastic waste when they are no longer in use. The new study shows that it is possible to combine molecular gastronomy concepts with biodegradable materials to create such devices that are not only environmentally friendly, but also have the potential to outperform the non-sustainable ones.

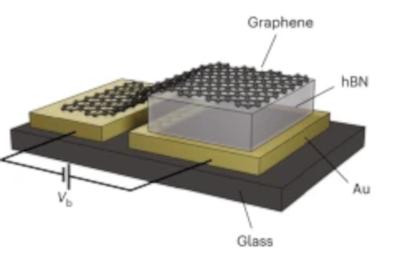

Graphene is known to have an extremely quick response to incoming light, which leads scientists to believe it can potentially lead to applications like ultrafast photodetectors that could meet the ever-growing demand for internet bandwidth. However, graphene's exceptional thinness means that it absorbs light poorly, typically tapping only about 2% of a laser beam’s energy.

Now, scientists from Switzerland's ETH Zurich have shown how graphene’s speed might be exploitable after all, by integrating it with a tailor-made infrared absorber—a metamaterial consisting of an array of tiny gold antennas. The researchers have reportedly demonstrated a world-record photodetection bandwidth of 500 GHz combined with a flat frequency response across a broad part of the near-infrared spectrum. Although the device’s overall absorption still remains fairly low, they believe that its ability to deal with high input powers combined with further design optimizations could enable a new generation of graphene-based photodetectors.

In April, First Graphene (FGR) announced plans for major graphene-enhanced cement trials with a consortium that includes Breedon Cement, Morgan Sindall and the University of Manchester. Now, FGR confirmed the beginning of these trials using the company’s graphene in cement and concrete at the Breedon Group’s Hope Cement Works at Derbyshire in the United Kingdom.

The trials aim to build on smaller-scale trials with an accredited concrete processing laboratory in the UK, which First Graphene said “generated positive results”, and to further showcase the carbon dioxide reduction benefits of graphene additives. According to the company, the trial – with Breedon, Morgan Sindall Construction and the University of Manchester – will use approximately 1.2 tonnes of PureGRAPH 50 and create about 2,000 tonnes of graphene-enhanced cement at the works.