Graphene-Info Newsletter—2 pieces on Zen Graphene

posted on

Oct 05, 2021 10:58AM

Hydrothermal Graphite Deposit Ammenable for Commercial Graphene Applications

Cannot read this? View it online here

G6 Materials (Formerly called Graphene 3D Lab) reported its financial results for its fiscal year which ended on May 31, 2021. The company's revenues reached $1.9 million, a 110% increase from last year. G6M attributes most of its growth to strong demand for its air purification products and graphene-related consulting services.

G6 Materials' comprehensive loss decreased by 6% to $938,600. At the end of the year, total assets grew 407% to $5.9 million.

Researchers at Shanghai Jiao Tong University, Stanford University, and other US and China institutes have designed a strategy for creating graphene nanoribbons (GNRs) with smooth edges that are below 10 nm in width. This new method is based on the use of squashed carbon nanotubes (CNTs).

The team explained that the idea behind this new work is that if carbon nanotubes (CNTs) can be squashed into GNRs, it would be possible to produce narrow (sub-5-nm wide) GNRs from CNTs that have small diameters. The team said that the GNRs prepared using this method would be much narrower than those obtained by previous methods.

CamGraPhIC recently raised £1.6 million through an equity funding round from existing and new investors.

The fundraising values University of Cambridge spin out CamGraPhIC at £5.6 million pre-money. It brings total funds raised by the Company to £3.4 million including the loan facility announced by the Group ןn July 2021.

For many years, scientists have been trying to harness Bloch oscillations, an exotic kind of behavior by electrons that could introduce a new field of physics and important new technologies. Now, MIT physicists report on a new approach to achieving Bloch oscillations in recently introduced graphene superlattices. Graphene's electronic properties undergo an interesting transformation in the presence of an “electric mesh” (a periodic potential), resulting in new types of electron behavior not seen in pristine materials. In their recent work, the scientists show why graphene superlattices may be game changers in the pursuit of Bloch oscillations.

Normally, electrons exposed to a constant electric field accelerate in a straight line. However, Quantum Mechanics predicts that electrons in a crystal, or material composed of atoms arranged in an orderly fashion, can behave differently. Upon exposure to an electric field, they can oscillate in tiny waves—Bloch oscillations. “This surprising behavior is an iconic example of coherent dynamics in quantum many-body systems,” says Leonid Levitov, an MIT professor of physics and leader of the current work. Levitov is also affiliated with MIT’s Materials Research Laboratory.

The Army Corps of Engineers will work with Prof. Tour and his collaborators at Rice University through a $5.2 million, four-year grant to expand the process that turns waste into graphene through flash Joule heating, to additional materials as well. Among the initiatives is a strategy to recover cobalt, lithium and other elements through the process developed by Tour’s group.

The grant through a Department of the Interior Cooperative Research and Development Agreement will allow the Rice-based team to extend the impact of its discovery that “flashing” food waste and other trash with a high-voltage jolt of electricity turns it into graphene. Through further experiments, the team realized the process could do much more. “We’re pushing the idea that flash Joule heating can go way beyond just graphene,” Tour said.

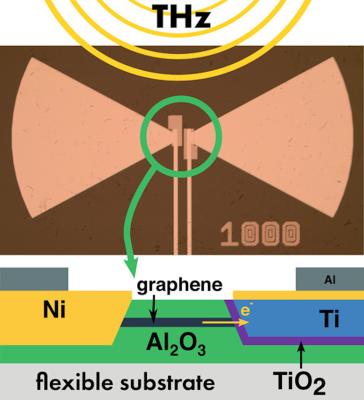

Researchers from AMO GmbH, RWTH Aachen University, Chalmers University and the University of Wuppertal have recently developed a novel type of graphene-based flexible energy harvester, which reportedly shows good prospects for powering wearable and conformal devices.

The device is a 'rectenna' - an antenna directly coupled to a diode, which is able to detect radiation and to transform it into a DC output. Rectennas working in the microwave region have been well established since the sixties, thanks to the availability of Schottky diodes with a sufficiently short response time. The challenge is to extend the working principle of rectennas to higher frequency ranges – in particular terahertz (THz) and optical frequencies.

ZEN Graphene Solutions recently announced the signing of a definitive commercial agreement with Trebor Rx for the manufacturing of ZENGuard™-enhanced personal protective equipment. The agreement includes surgical masks, filters for Trebor’s patent pending Pro+ mask, nitrile gloves and other potential products.

Greg Fenton, Zen's CEO, commented: ”After working closely with George Irwin and the Trebor team over the last year, we have developed an excellent working relationship and are eager to launch our first product together, the Trebor Rx surgical mask with ZENGuard™ technology delivering over 99.99% bacterial and viral filtration efficiency. This is a significant commercial success for both our organizations, but more importantly, it brings a new option to healthcare employees and others in higher risk settings that wish to significantly enhance the bacterial and viral filtration efficiency compared to a typical, disposable ASTM level 3 mask.”

Elcora Advanced Materials recently announced the closing of the first tranche of its private placement, for gross proceeds of CAD$1,125,500 (around USD$889, 154) for the first tranche. The Company may issue further Units to raise total gross proceeds of up to CAD$3,000,000 (around USD$2,370,000).

The Company intends to use the net proceeds for general working capital purposes. Elcora was founded in 2011 and has been structured to become a vertically integrated graphite & graphene company. Elcora processes, refines, and produces both graphite & graphene. As part of the vertical integration strategy Elcora is securing high-grade graphite and graphene precursor graphite from operations in Sri Lanka and other countries which are already in production. Elcora has developed a cost-effective process to make high-quality graphite, graphite products and graphene that are commercially scalable.

Months after Health Canada deemed graphene-enhanced face masks as a "potential health hazard", ZEN Graphene Solutions announced receiving an approval from Health Canada for its ZENGuard™ disposable face mask with biocidal coating and is rated at an ASTM Level 3. An extensive review process took place, after which Health Canada validated ZENGuard™-enhanced surgical masks as 'safe for use by Canadians'.

In addition, ZEN Graphene Solutions also announced that it has delivered and generated revenue from its first shipment of ZENGuard antimicrobial coating to Trebor Rx. This first commercial shipment was enabled by a successful ramp up from bench scale production to pilot scale capacity, which currently exceeds the amount needed to coat 30 million masks per month. The company also reports that the engineering work on its industrial plant with an estimated capacity to coat the equivalent of 800 million masks per month is in the procurement stage. ZEN expects the build out and commissioning of the plant to be completed during the fourth quarter.

Foxconn has signed an agreement with Appear Inc to scale up Appear's fast charging graphene battery technology, for both consumer products and electric vehicles.

Appear Graphene Super 20 Powerbank

Appear Graphene Super 20 Powerbank

The two companies will collaborate, and Foxconn will provide its smart manufacturing and product development capabilities while Appear will provide the battery technology and IP.

Electric two-wheeler brand Yadea recently unveiled a number of products and innovations at its New Tech Launching Event, held in Wuxi, China. Among the achievements on display were Yadea’s Graphene 3.0 Battery, which the Company aims to to use to advance its electric two-wheeler technology.

Yadea’s Graphene 3.0 Battery reportedly boasts ultra-low temperature resistance, improved battery capacity and a high level of durability. The Company explained that it has added antifreeze electrolyte into the battery, which can dynamically adapt to different environmental conditions, adjust the battery temperature, and ensure that electric vehicle mileage doesn’t decline in winter. At the same time, the battery is said to be resistant to extreme temperatures and can handle ranges from -20°C to 55°C.

Specialists at The University of Manchester have teamed up with global architect firm Skidmore, Owings & Merrill (SOM) to research the design and manufacturing of space habitats for the space industry.

The view from inside the viewing deck aboard the Graphene Space Habitat. Credit: SOM and U of Manchester

The view from inside the viewing deck aboard the Graphene Space Habitat. Credit: SOM and U of Manchester

The international collaboration has Dr. Vivek Koncherry and his team (supported by the Manchester-based Graphene Engineering Innovation Centre) creating a scaled prototype of a graphene-enhanced space habitat with pressurized vessels designed to function in a space environment.

Tirupati Graphite has entered into a research collaboration agreement with Monash University in Australia to develop commercial applications for a range of graphene products in raw and recycled polymer nanocomposites and dispersions.

The 12-month agreement with the Department of Material Sciences and Engineering specifies that research will focus on enhancing thermal, electrical, and mechanical properties of various polymers and preparation of dispersions for developing a range of commercial products.